The Ultimate Guide To Flooring

Wiki Article

Flooring Installation - An Overview

Table of ContentsThe Wood Flooring DiariesThe Buzz on Flooring StoresWhat Does Flooring Installation Do?Things about Hardwood Flooring CostThe 6-Second Trick For Wood FlooringFacts About Flooring Installation RevealedThe Only Guide to Flooring

Before applying the second coat, examine the flooring for any problems. If there holes or splits, utilize the epoxy filler and wait for 12 16 hrs for it to dry.Our epoxy floor installers will also justify the material with specialist installment solutions.

Close this dialog home window Share & More Back to tale Discuss this task this web link is to an outside website that may or may not fulfill ease of access standards.

Flooring Installation - An Overview

The procedure of measuring, pigmenting, blending, dual potting, pouring as well as spreading is duplicated up until the floor is completed. Glass, Cast 3 epoxy finish resin has exceptional self-levelling buildings, so will only call for light functioning to make certain that it has complete protection and also a regular density - after that the material will do the remainder of the job.Glasscast 3 is additionally self-degassing so the bubbles will certainly stand out on their own, although we observed a small spot of floor where bubbles really did not appear to be popping - this could be because of a tiny spot of flooring not being pre-sealed - to conquer this we quickly overlooked the surface with a gas torch to rupture them.

As soon as you enjoy with the flooring it's time to seal the space and also leave it to completely heal - this will enable the resin to degas, self-level and remedy to an amazing high gloss coating like this! Remember it is extremely crucial to secure the area to ensure that there are no drafts as this might cause dirt and debris to land in the resin throughout the treatment.

Wood Flooring Things To Know Before You Get This

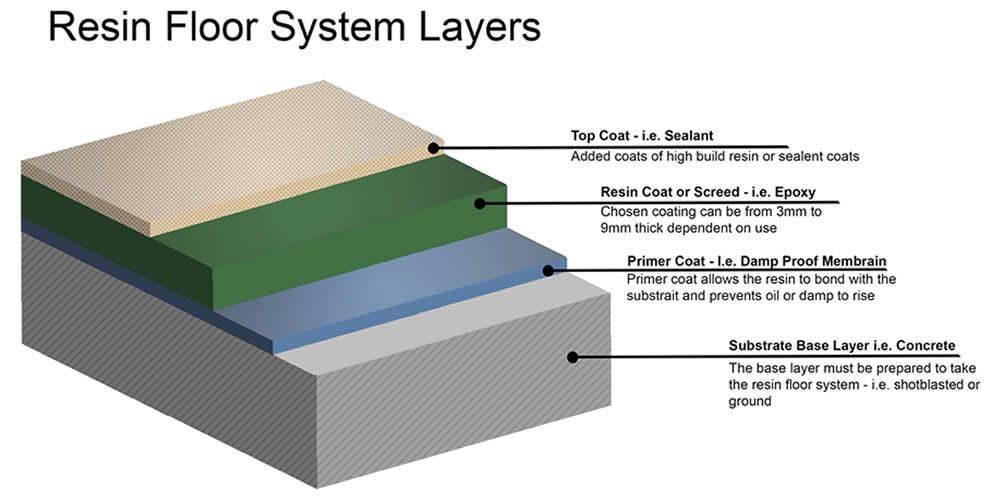

The listed below overview is a summary of the steps on exactly how to apply epoxy flooring paint. This overview puts on an easy roller used flooring. Such epoxy systems are usually applied with one layer of primer & 2 coats of epoxy flooring covering. These floorings are ideal for light and also medium wear and tear, perfect for garages and also storage areas.A Self progressing epoxy floor has a tendency to have a. Preparing the surface area prior to using the epoxy Preparation of the substratum is required in order to guarantee attachment in between the epoxy product and also the substrate.

Vinyl Flooring Fundamentals Explained

Making use of a floor grinder permits you to make use of different sorts of grinding tools relying on your requirements. For instance if you need to grind rough concrete, you require to use an aggressive and rugged diamond tool. If you need to provide the existing surface a light sanding, you can choose instead to make use of a high grit sanding tool.This is why we apply epoxy primer. Always prime the floor, don't think claims that priming is not essential. Priming will provide your floor a longer life and also better bond to the substratum. It will seal the substratum and also decrease the danger of bubbles as well as gasses in your final epoxy coat.

Guarantee that the locations are aerated effectively. In some cases, you will use the guide as well as notification that the product gets extremely promptly taken in by the substrate. This is very common with messy as well as soft cement based floors. on top of the very first one. Utilize a proper electric mixer to blend the An and also B part of the primer.

The Definitive Guide for Flooring Installation

Most likely it will certainly additionally require a little of fining sand prior to continuing to the following action. Several days have probably passed considering that you began the process of mounting your epoxy flooring. Check This Out If you have done all the previous actions correctly, you are lastly ready to use the very first layer.

Likewise often be in the very first layer. If you applied the initial layer with a squeegee lots of line marks might be visible. You will certainly require to gently sand these areas to get rid of any type of marks that could be visible on the last flooring. Make use of a vacuum cleaner to accumulate any kind of dirt.

Flooring Stores Things To Know Before You Get This

Ensure that all the new fractures as well as holes are sealed & filled before starting the next layer. If essential wait an additional completely dry for the cement to dry prior to re-coating. If you followed the epoxy flooring process in this post, after that the final layer get more must be the simplest step.

This course was developed for applicators that want to obtain into epoxy floor covering. You will certainly get that has actually been distilled right into over 20 lessons - flooring stores.

The Facts About Hardwood Floor Installation Revealed

Step 2: Examine Weather Report Before you begin ensure the air temperature is 60 degrees and also rising which your piece goes to a minimum of 50 levels. It will be near difficult for the epoxy to set if you attempt to do this in the wintertime. Action 3: Sweep It Completely Make use of a broom to clean up the slab.The goal is to not click over here now over-wet the flooring so it will likewise dry promptly. Step 6: Apply Etch Pretreatment Mix the citric acid concrete etch with cozy water per the guidelines. Use, scrub, as well as squeegee off the flooring in the very same way as the degreaser. The citric acid will help open the top pores of the concrete so the epoxy adheres well.

Allow much longer dry times in cooler temperature levels. Tip 8: Examination For Existing Sealant Examine to see if there is still top sealer on the flooring. Drip water onto the piece. If the water grains up, there is an existing sealer that might disrupt the adhesion of the epoxy. Depending on exactly how much sealant is left, you might need to duplicate the etching procedure.

Report this wiki page